seamless 3D assembly

Seamless assembly has been replacing the former technology of “stitched seams”, but the revolution was not yet complete. That is, until today.

Hitherto, seamless technology was limited when it comes to 3D assembly. It was usually obtained with standard 2D presses equipped with complementary 3D models, a solution with two main limitations.

But this was the past.

![]()

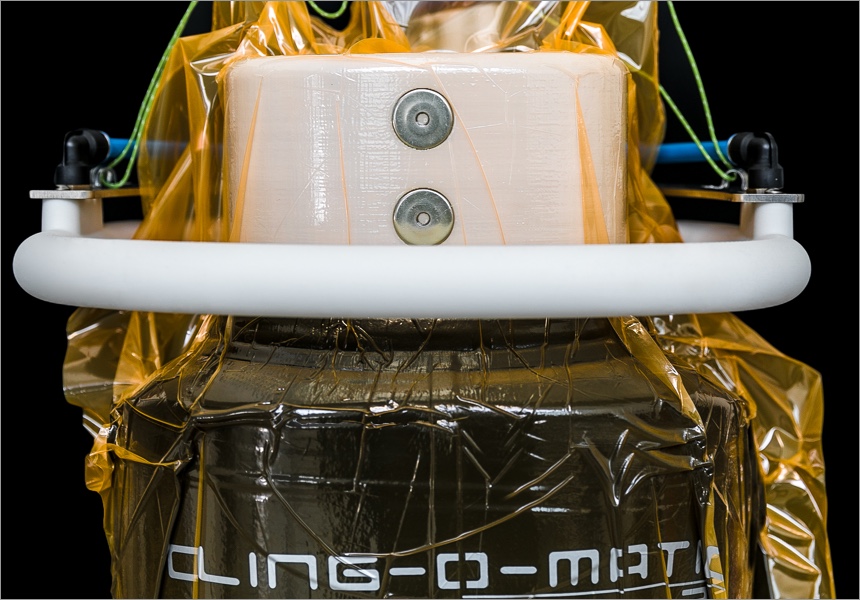

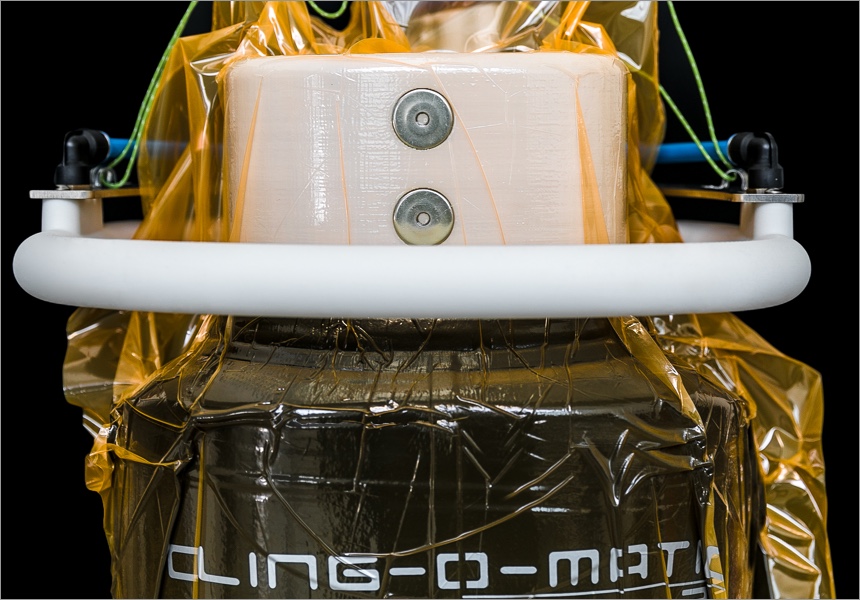

The Cling-o-matic® solution is a patented technology (Patent no. 102015000037266), which solves these problems with a new concept: the flaps are positioned on a single 3D support and pressure is exerted by the atmospheric pressure and transferred through a flexible element in a perfectly even and controlled manner.

Atmospheric pressure is used at 99.5% through a vacuum generation system, obtaining an adhesion pressure of around 1kg/cm2, equivalent to the most powerful flat presses.

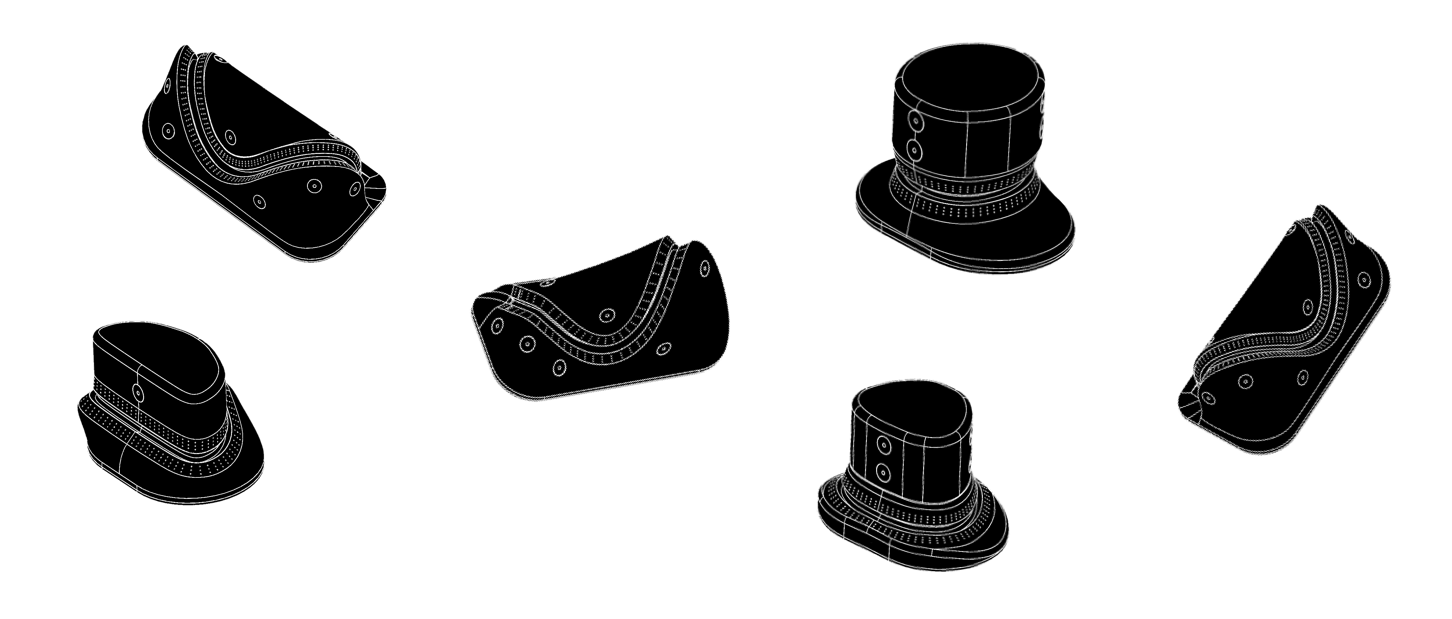

The shape of the support is calculated by proprietary software. Currently available software tools do not offer solutions that can handle surfaces that are flat and flexible, but not extensible, and bend them to match in a 3D space.

Our software is a program in which it is possible to input flat shapes with any outline, even complex, with variable radii of curvature and reversals of curvature, and composes two of these curves in the 3D space, as long as they have the same total length, according to an angle of incidence that can be varied as required, but which is constant for the whole of the coupling profile.

Supports are developed thanks to our proprietary software and can be custom made to match any design requirement. They offer an easy technique of textile placement to guarantee the quality of the final product.

Pressure is guaranteed by the vacuum generated by the machine, which allows the atmospheric pressure to exert its force on the flexible element, which in turn transfers it to the parts to be assembled.

Only the sealing edge is heated to a high temperature, while the rest of the garment is not heated. This solution prevents damage to any pre-existing seals or to any nearby element in the garment that might be subjected to unnecessary heating.

After sealing, cool air is blown onto the sealed edges while the garment is still clinging through pressure so that glue can polymerize with no spring-back of the fibres. The result is a perfect seal capable of withstanding strong tensile stresses and remaining stable in time.

The quality of garments assembled with Cling-o-matic® is guaranteed by:

No more irregular expansions, no more segmented or superficial sealing of the parts to be assembled: with Cling-o-matic® the garment is assembled in 3D and on the whole segment of the curve, offering greater coupling strength while accurately following the curve or rotundity of the model.

* The tensile strength test on the seal, carried out on a laminated fabric, reached a value of 29.42 kg/cm2 before tearing of the fabric.